Simple Design

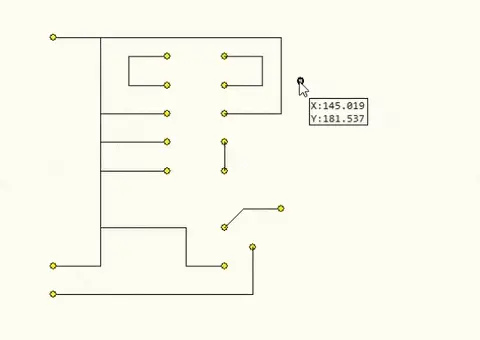

CADasCAM has many built-in features to make design quick and easy.

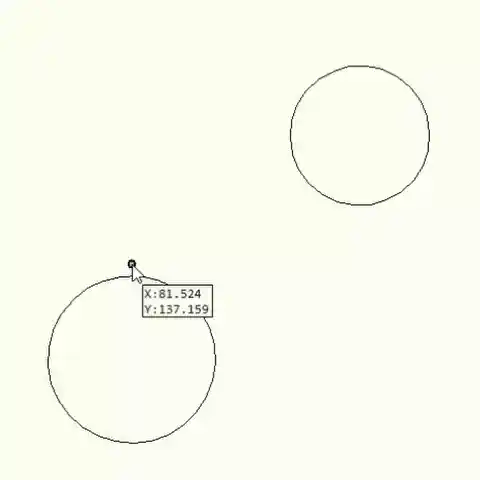

- Intelligent snap functions of geometrically relevant points

- Automatic generation of auxiliary lines in the design context

- Extensive geometry generation from lines and circular arcs to freeform curves and more complex geometry formations

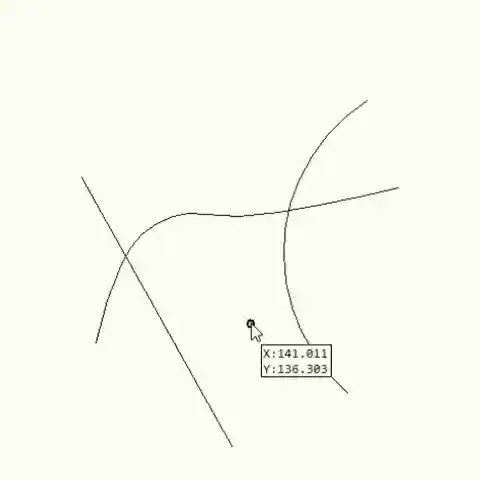

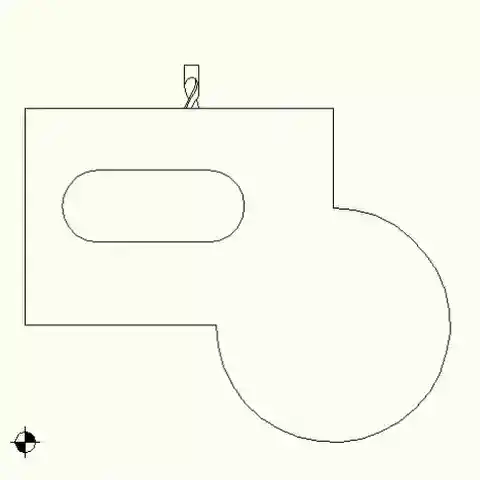

Trim, Modify, Delete

Extensive trimming functions:

- lengthen/shorten/separate with automatic intersection detection

- Fillets, chamfers, radii and undercuts

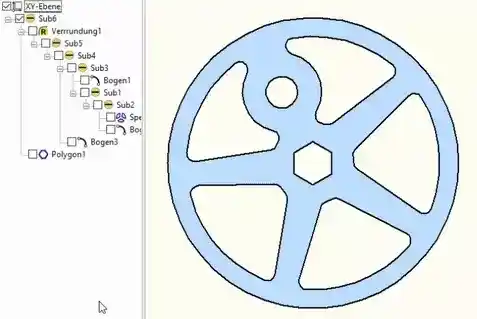

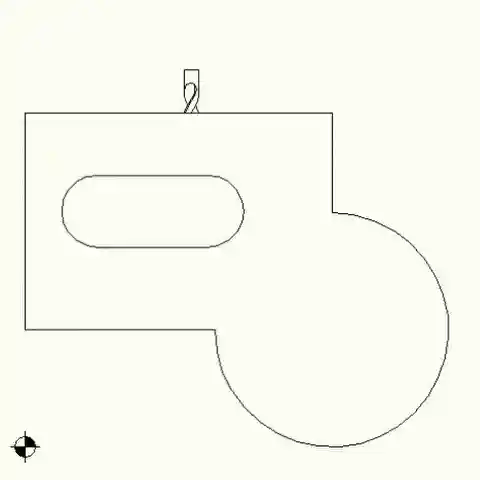

Figures

Parametric design made easy. CADasCAM offers you a 'construction kit' with figures of all imaginable shapes, which can be merged, intersected and modified in many ways by means of operations.

Operators

With the figures, parametric structures can be built up in a flash. You don't like a value? Change it afterwards, and the rest of the construction adapts.

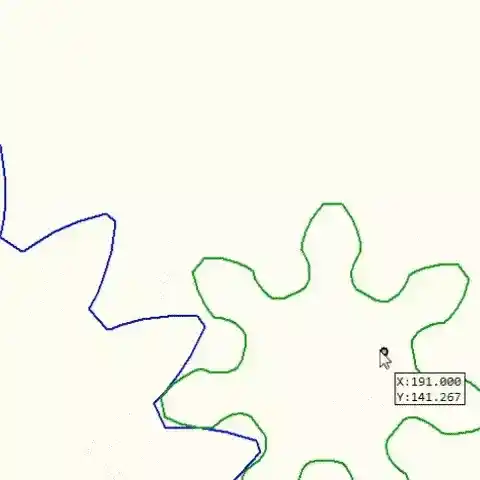

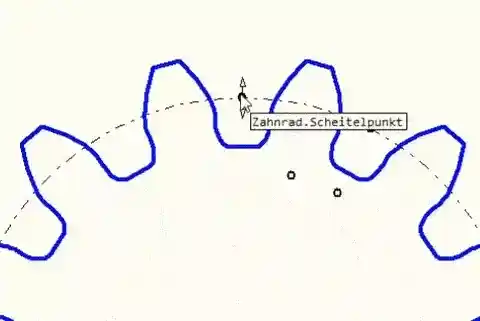

Gears

Gears are implemented in CADasCAM as separate figures. You can design cylindrical gears, hollow gears or racks and position them relative to each other if the profile is compatible.

Gear geometries

A gear can be created with 3 clicks. After that, module, number of teeth and almost all parameters of the involute profile can be adjusted.

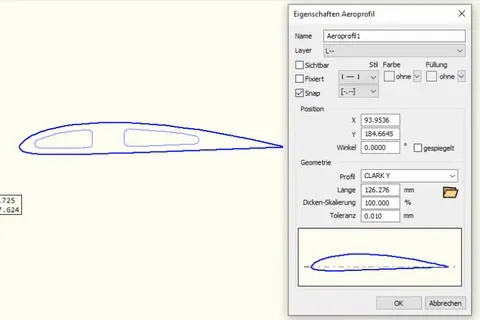

Aeroprofiles

Give your project wings! The Aeroprofile feature lets you import, customize, and edit various wing profile shapes.

Conductor paths

If you want to mill circuit boards, you can use the integrated trace function to convert lines and points into traces and eyes.

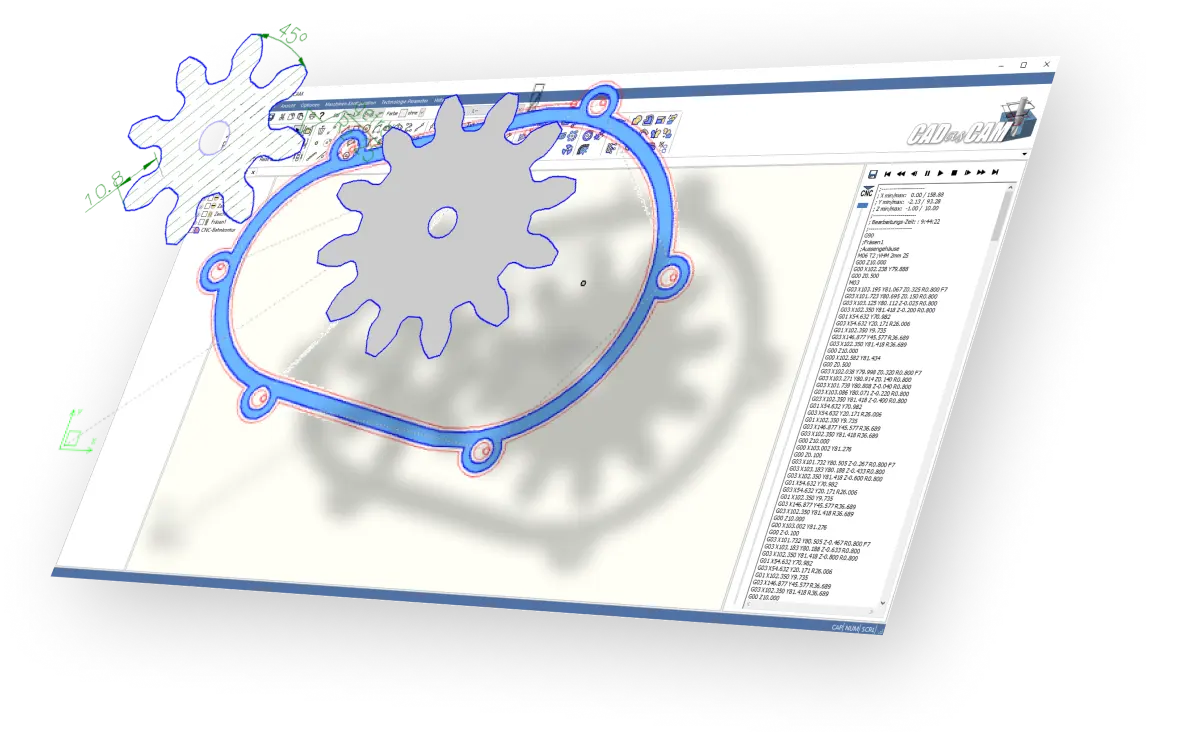

CNC path creation

Choose from a variety of machining strategies. Axis or contour parallel pockets, face milling, coordinate drilling, center path with or without path correction. CADasCAM can also thread whirling and drag knife cutting.